In a breakthrough for data centers worldwide, researchers at the University of Texas have developed a thermal interface material (TIM) that cools up to 72% more effectively than current thermal pastes, reducing the need for power-consuming cooling solutions like pumps and fans. This development is particularly crucial as data centers face rising temperatures from increased processing demands and energy use.

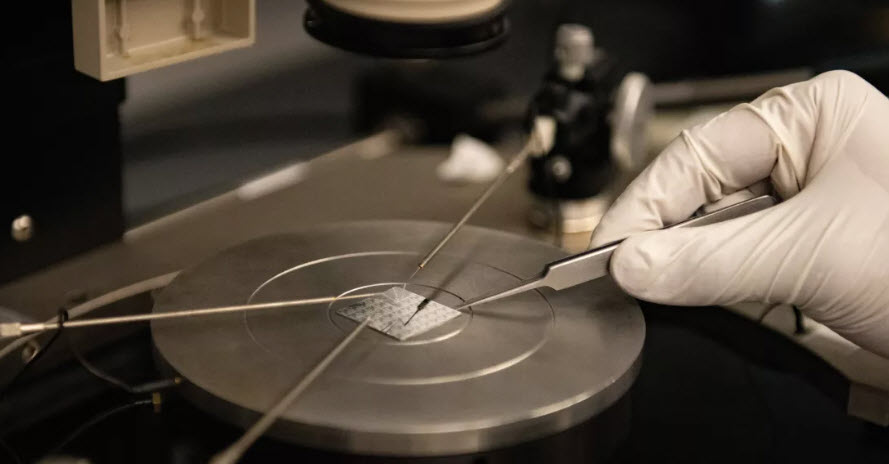

This innovative TIM, engineered through a unique blend of liquid metal alloy Galinstan and ceramic aluminum nitride, was shown in lab tests to dissipate an impressive 2,760 watts of heat from a 16 cm² area. This unprecedented heat transfer efficiency results from gradient interfaces created through mechanochemistry, allowing smoother heat flow.

New thermal interface can lower the cost of cooling by %13

With cooling expenses comprising 40% of data center energy use — equating to around 8 terawatt-hours annually — the new thermal interface material could lower these costs by 13%, effectively cutting data center energy use by at least 5%. If successfully scaled, this material could drive down both operational expenses and carbon emissions across the tech industry.

Although still in the testing phase, with real-world trials forthcoming, this TIM may eventually allow data centers to house more processors in smaller spaces without overheating, revolutionizing data center cooling. While a consumer-ready version remains distant, this advancement marks a promising leap forward in sustainable tech solutions.

For more in-depth insights, see the study in Nature Nanotechnology.