While Stellantis has stepped back from some planned electric vehicle projects, such as the all-electric Ram REV and the high-end Dodge Charger Daytona R/T EV, it’s not stopping in safety technologies. A newly acquired patent from the company outlines an innovative, foam-based thermal runaway suppression system embedded in an electric vehicle’s battery pack.

Foam-Based Fire Suppression System Patented!

It’s an undeniable fact that electric vehicles (EVs) far rarely cause fires compared to their internal combustion engine counterparts. However, some early Tesla fires that received widespread media attention, and the poorly managed recall of the first-generation Chevy Bolt, have linked the words “electric car” and “fire” in the minds of many Americans. For those expecting a better safety solution, this latest patent from Chrysler’s parent company Stellantis could provide a significant confidence boost.

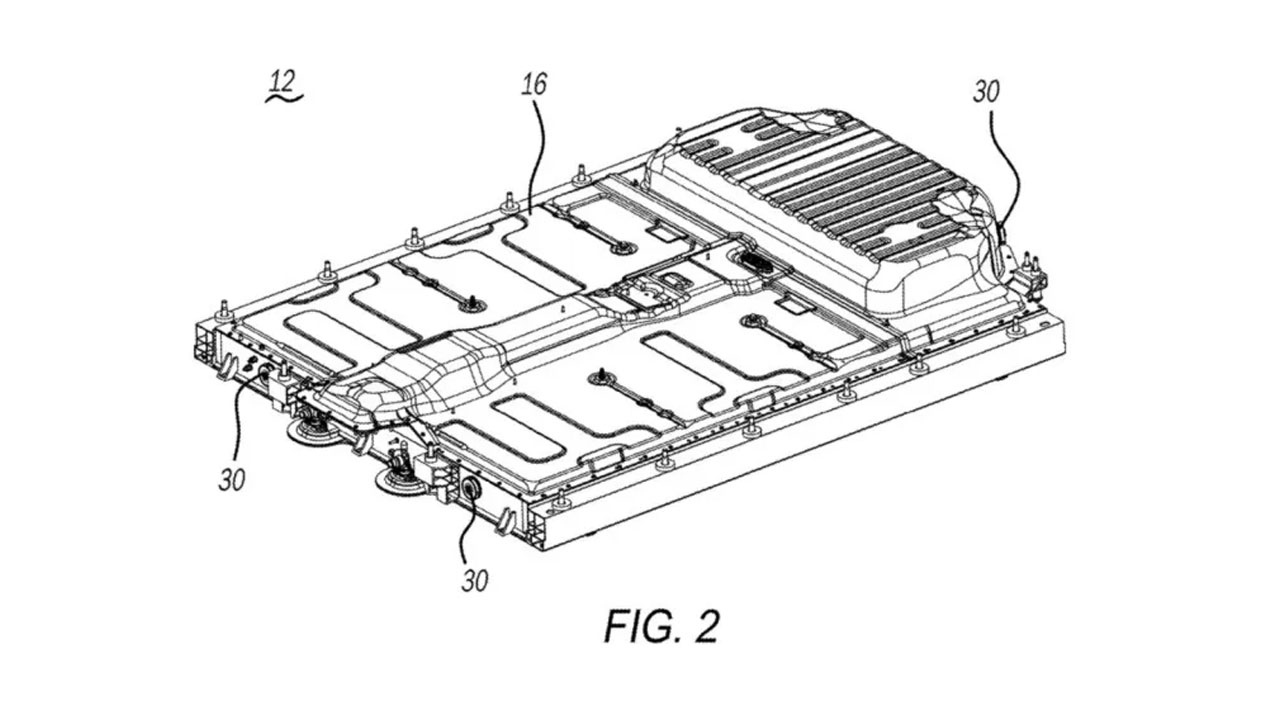

The new Stellantis patent, reported by MoparInsiders, details a proactive battery safety system designed to prevent a thermal runaway (i.e., a fire) from spreading throughout the entire battery pack.

Instead of relying solely on passive barriers or post-incident containment, Stellantis’s patented new system utilizes strategically placed foam channels and distribution mechanisms that can fill affected cells with highly insulating foam when abnormal heat is detected in the cells. This works by isolating the problem area and significantly slowing (or even completely stopping) the chain reaction that leads to catastrophic battery failure.

The patent describes an electric vehicle battery that will look familiar to EV enthusiasts from the outside, but with some key differences “layered” around the familiar parts:

- Fire Retardant Chemical Bag: A flexible polymer bag (ready to be punctured when needed) filled with a fire retardant chemical, placed near the battery cells, usually between the cells and the top of the pack.

- Two Blade Sets: The first is directed into the bag to puncture it and release the fire retardant chemical, while the second is designed to target specific points on the coolant inlet line, outlet line, or heat sinks, blasting them and releasing coolant foam directly where needed. Special Refrigerant Line Sections: Special refrigerant line sections with small, sealed openings that the blades could easily puncture but are strong enough to maintain pressure during normal operation, sealed with a soft plug material.

- Control-Connected Actuator Devices: Activation devices that push the blades into the bag and refrigerant components when a thermal event is detected.

- The system relies on a series of temperature sensors available throughout the battery pack and appears to be a highly viable solution to a problem that, while rare, certainly exists and places significant pressure on “Early Majority” technology adopters in America.