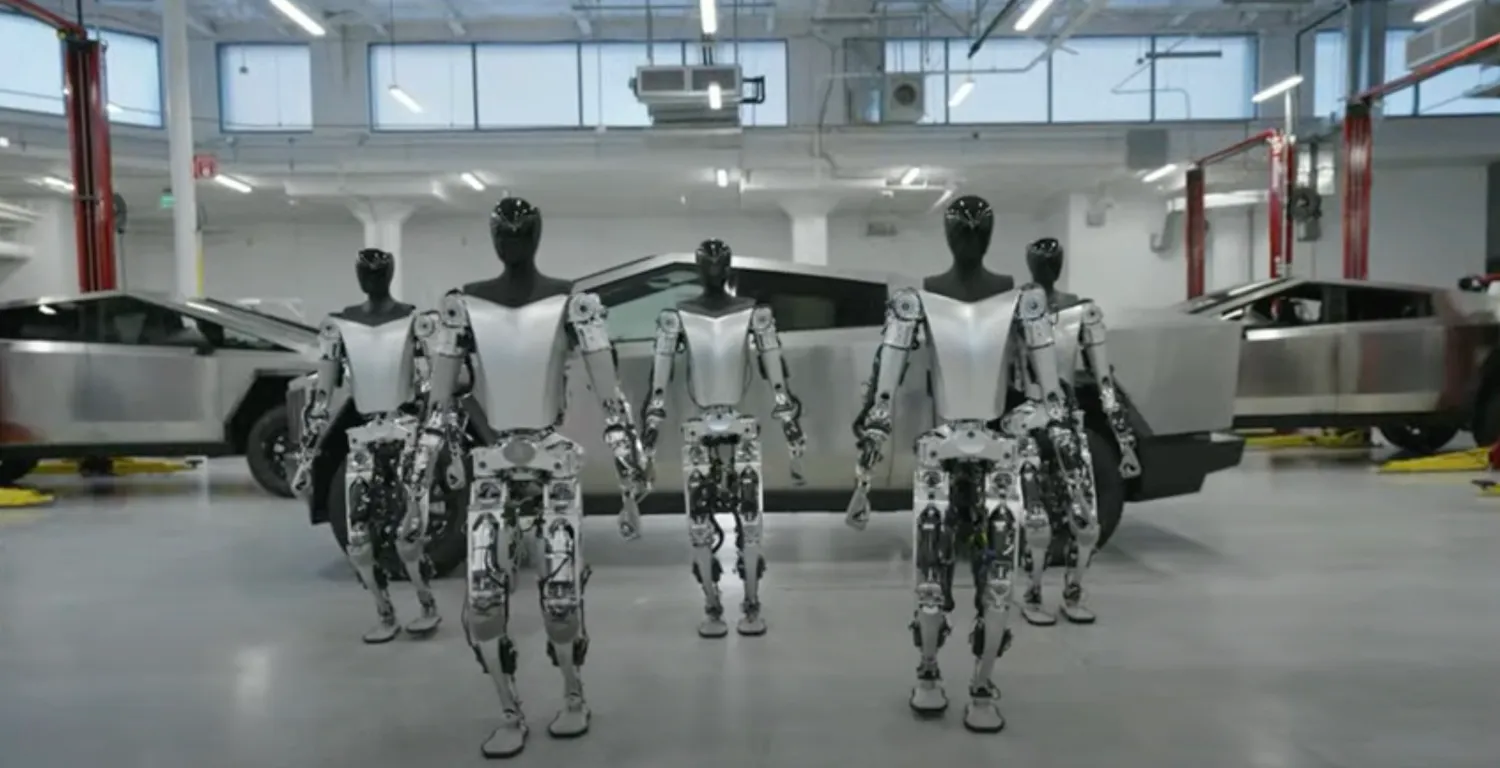

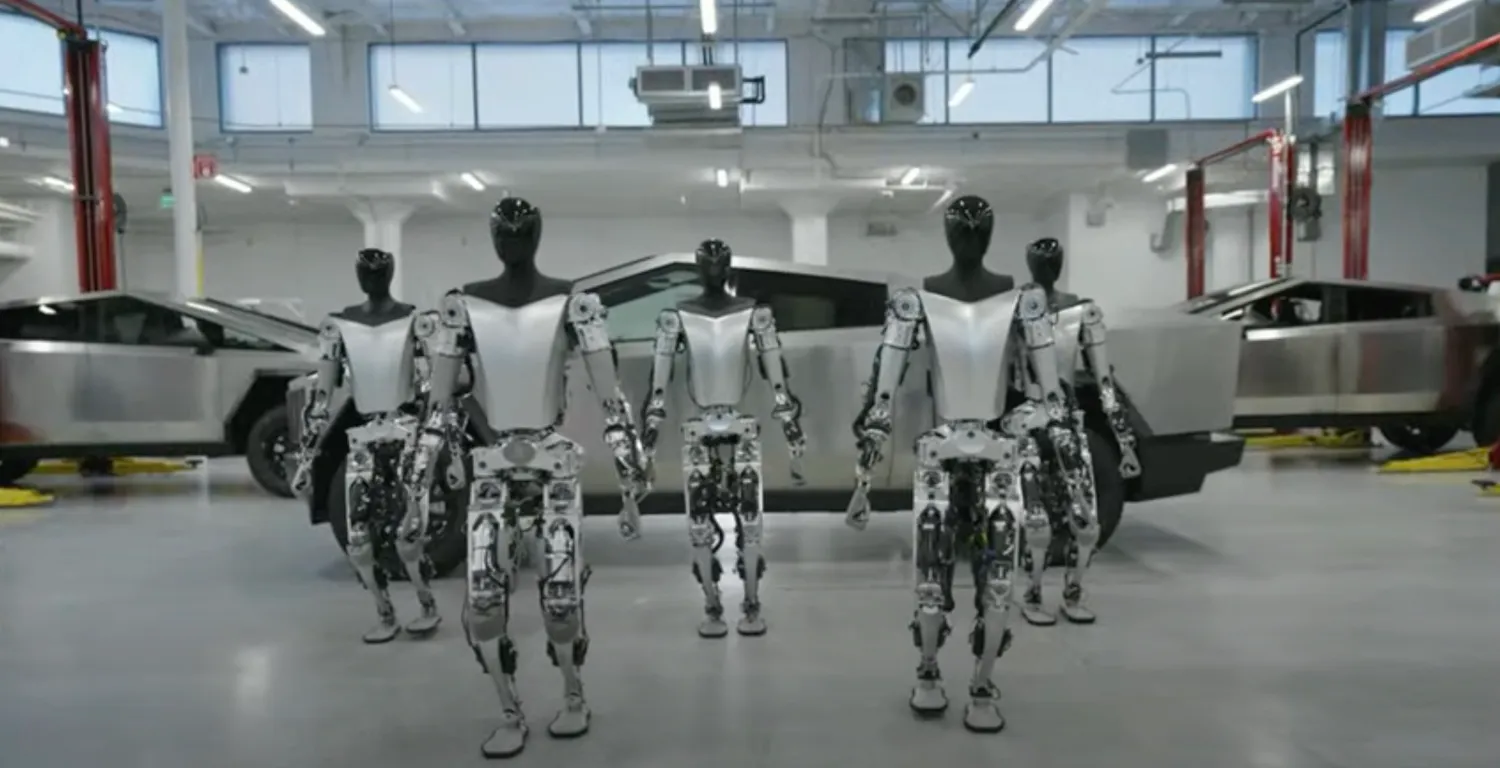

Tesla has officially moved its Tesla Optimus robots from research and development to the factory floor, deploying over 1,000 units across its global manufacturing facilities. These advanced humanoid robots are now performing autonomous tasks previously handled by human workers, with a significant concentration at the Texas Gigafactory and Fremont plants. This move represents the first major large-scale commercial use of general-purpose humanoid robots in a high-speed production environment.

How Tesla Optimus Robots Are Changing Manufacturing

Unlike traditional industrial robots, which are typically bolted to the factory floor and programmed for a single task, the Optimus units offer remarkable flexibility. These robots are already active on Tesla’s 4680 battery cell lines, where they navigate complex and unscripted environments with ease. Furthermore, they can identify misplaced components and perform delicate assembly and fastening tasks with human-like dexterity.

This technological leap is made possible by the Optimus Gen 3 platform, which utilizes a beam-driven system with powerful actuators in its forearms. The robot’s hands, featuring 22 degrees of freedom, are equipped with integrated tactile sensors that can dynamically adjust pressure. This allows them to handle both fragile plastic clips and heavy metal brackets with the same level of precision.

The ‘Physical AI’ Behind Optimus’s Rapid Learning

The intelligence driving the hardware is Tesla’s FSD-v15 neural architecture, an evolution of its Full Self-Driving software. Dubbed “Physical AI,” this system perceives the robot as a vehicle with hands and legs. Instead of relying on traditional programming, Optimus learns new tasks by watching videos of human workers. Consequently, it can master new skills in a matter of hours, a process that would otherwise take weeks of coding.

According to Dr. James Miller, a robotics researcher at Stanford University, Tesla has successfully bridged the gap between simulation and reality. By leveraging data from millions of its vehicles, Optimus gains a natural understanding of the physical world that competitors struggle to replicate even in virtual environments.

However, the competition is intensifying. Boston Dynamics has begun mass production of its Atlas robot for use in Hyundai and Alphabet facilities, while the Microsoft and NVIDIA-backed Figure AI is accelerating the deployment of its Figure 03 model in partnership with BMW. In response, Tesla has set an ambitious goal to produce 50,000 Optimus units by the end of 2026. The company has also started construction on an “Optimus Megafactory” in Austin, which is planned to produce 10 million robots annually.

While current models can operate for 8 to 10 hours on a single charge, part wear and tear from continuous use remains a challenge. With a targeted production cost of $20,000 per unit, analysts predict that the Optimus division could eventually become more valuable than Tesla’s core automotive business.

So, what are your thoughts on this rapid increase of humanoid robots in factories? Share your opinions with us in the comments!