Adidas has launched a lace-up version of its Climacool model, produced using 3D printing technology, for sale internationally. First announced in September 2024 and designed without laces, the shoe went on sale globally on May 2, 2025, with a price tag of $140. This lace-up design was criticized by some users.

Adidas Launches a 3D Printer-Designed Shoe

In response to this feedback, the company developed a lace-up version of the same model. Priced at $160, the new Climacool model was initially released in limited quantities through the “CONFIRMED” platform.

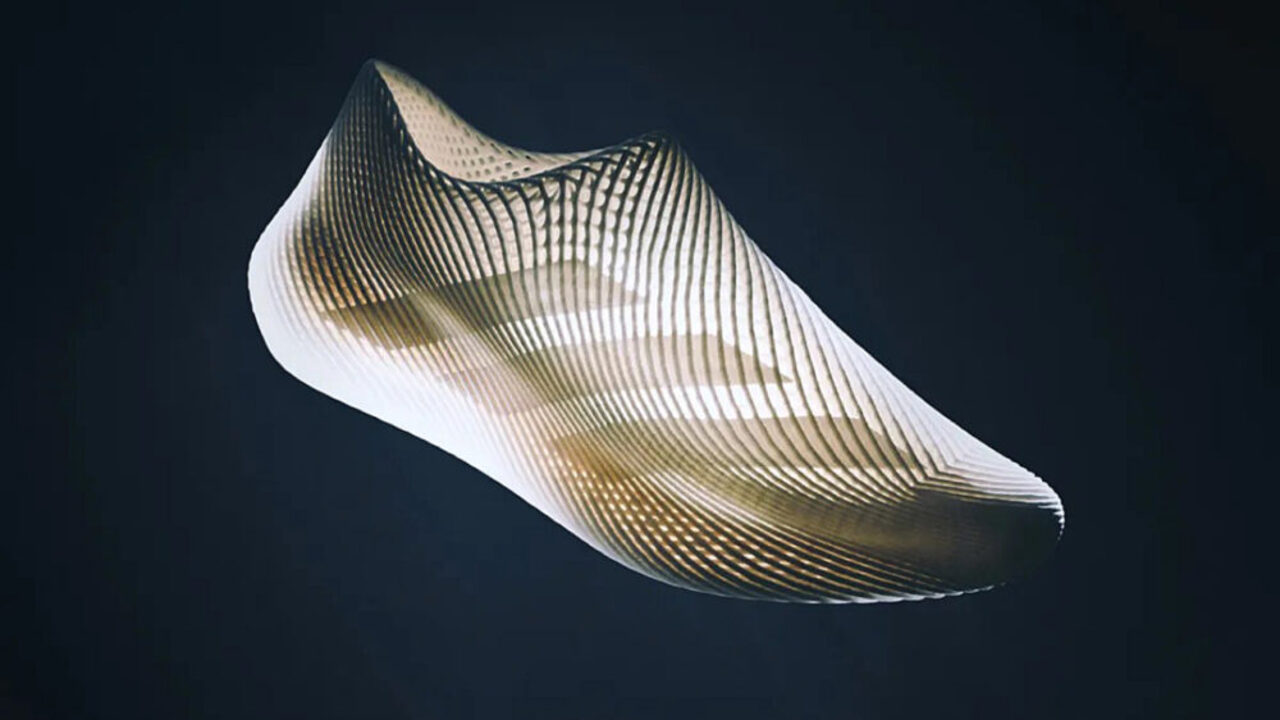

Adidas has been working on shoe production using 3D printing technology for a long time. The Climacool model stands out as one of the most recent examples of the advancements made in this technology. The shoe’s design provides 360-degree ventilation.

Thanks to its fully breathable upper, the shoe is said to be extremely lightweight. The product description states, “Climacool adapts, breathes, and virtually disappears on the foot.”

The new version maintains the breathability and flexibility of the original model, while also being expected to appeal to a wider range of users with the addition of laces. The shoe’s limited edition and innovative production method have made it a standout product in both the tech and fashion worlds.

3D-printed shoes have recently attracted the attention of various brands. Another notable example was the Nike Air Max 1000. Developed in collaboration with the Berlin-based company Zellerfeld, the model was largely produced using a single piece of 3D printing.

Inspired by the 1987 Air Max 1, the shoe, designed for commercial use and inspired by Nike’s innovation chief, can be produced in any color. Nike’s innovation chief, John Hoke, stated that this shoe “enabled them to explore production solutions that were previously impossible.”

Adidas’ Climacool model, with its lace-up version, represents a significant update in terms of both technological innovation and user expectations. This example of 3D printing technology being adapted for mass production and becoming commercially available also offers insights into the future of production methods in the footwear industry.