Apple has opened the doors of its product testing lab, which it has rarely shown to the public before, to a wider audience for the first time this year. As part of WWDC 2025, technology research organizations and a limited number of guests had the opportunity to closely examine the company’s durability testing center in California. This visit revealed with concrete data how many Apple devices, especially the iPhone, go through rigorous testing processes before they are released to the market.

Apple opens the doors of its testing lab

Apple’s testing procedure is divided into four main categories that measure how resistant devices are to environmental conditions, liquids, impacts and vibrations. The company’s engineers simulate the climate conditions of 175 countries around the world in a laboratory environment.

For example, iPhones are tested for one hundred hours in conditions equivalent to the intense dust environment of the Arizona desert or the seashores with high humidity and salt content. These tests do not only cover phones. Products such as AirPods are also tested with artificially created samples of sweat, earwax and other biological substances.

Apple applies protocols that go beyond the IP68 certification criteria in water resistance tests. Models such as the iPhone 16 Pro are tested to be able to operate without damage for one hour at a depth of six meters.

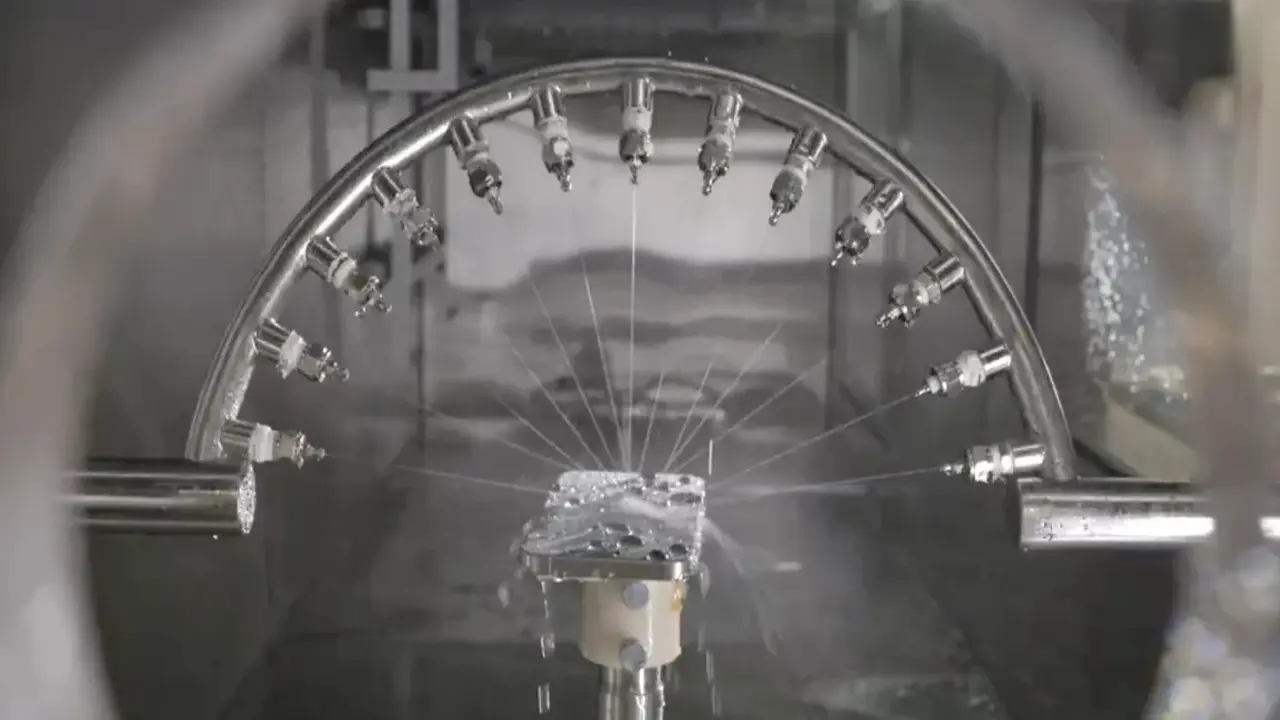

The testing process is not limited to fresh water; the devices are also exposed to real-life liquids such as sunscreen, soda, fruit juice and salt water. The effects of these liquids are analyzed using specially developed high-pressure spray systems and immersion tanks.

Apple’s drop and impact tests are also based on high technology. The products are tested by dropping them from different angles, different heights and onto different types of surfaces (such as asphalt or granite) using robotic arms.

The damage the device receives after each impact is analyzed in detail using special software. In line with this data, not only the external physical durability but also the resistance level of the internal components are evaluated.

Vibration tests, on the other hand, aim to measure how devices such as the iPhone respond to shocks during transportation and use. The devices are tested by placing them on vibration platforms that can operate over a wide frequency range.

So what do you think about this issue? You can share your opinions with us in the comments section below.