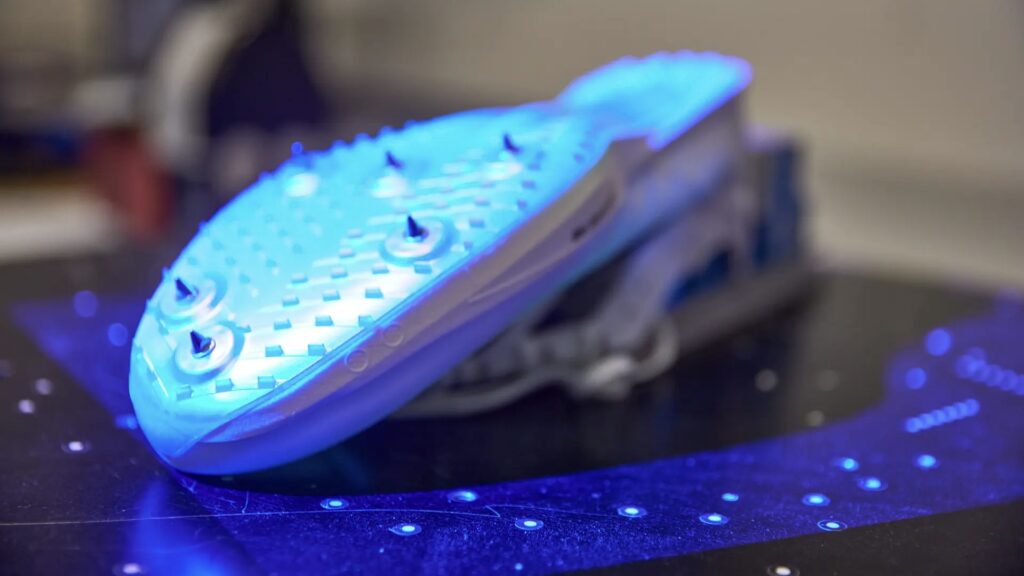

BMW is manufacturing sports shoes with 3D printed traction supports for the 2026 Winter Olympics. Their innovative printing technology is set to revolutionize the sports world, offering customized shoes designed to enhance athletes’ performance. Here are the details…

BMW Produces Sports Shoes with 3D Printing Technology

BMW uses 3D printing technology in the design and manufacturing process of shoes to maximize performance on ice. Tailored to each athlete’s foot structure, these shoes can be customized according to individual needs and preferences.

In bobsleigh, the speed and acceleration achieved during the pushing phase have a decisive effect on the race outcome. BMW’s sports shoe models allow athletes to execute more secure and controlled pushes on the ice.

Where Technology Meets Performance

The production process of these customized shoes takes place at BMW’s Additive Manufacturing Center. Here, durable and lightweight spike soles are produced using high-precision laser technology, which layers metal powder.

These shoes were first tested during World Cup trials, receiving positive feedback for the sports shoe models developed by BMW. Athletes praised the comfort of the shoes and the increase in performance.

BMW continues to refine this technology and aims to provide the most suitable shoes for athletes by the 2026 Winter Olympics. It seems that BMW’s customized sports shoe models will be a boost to athletes’ performance.

What are your thoughts on this development? How do you assess the entry of the major car manufacturer into the sports shoe industry? We look forward to your comments…