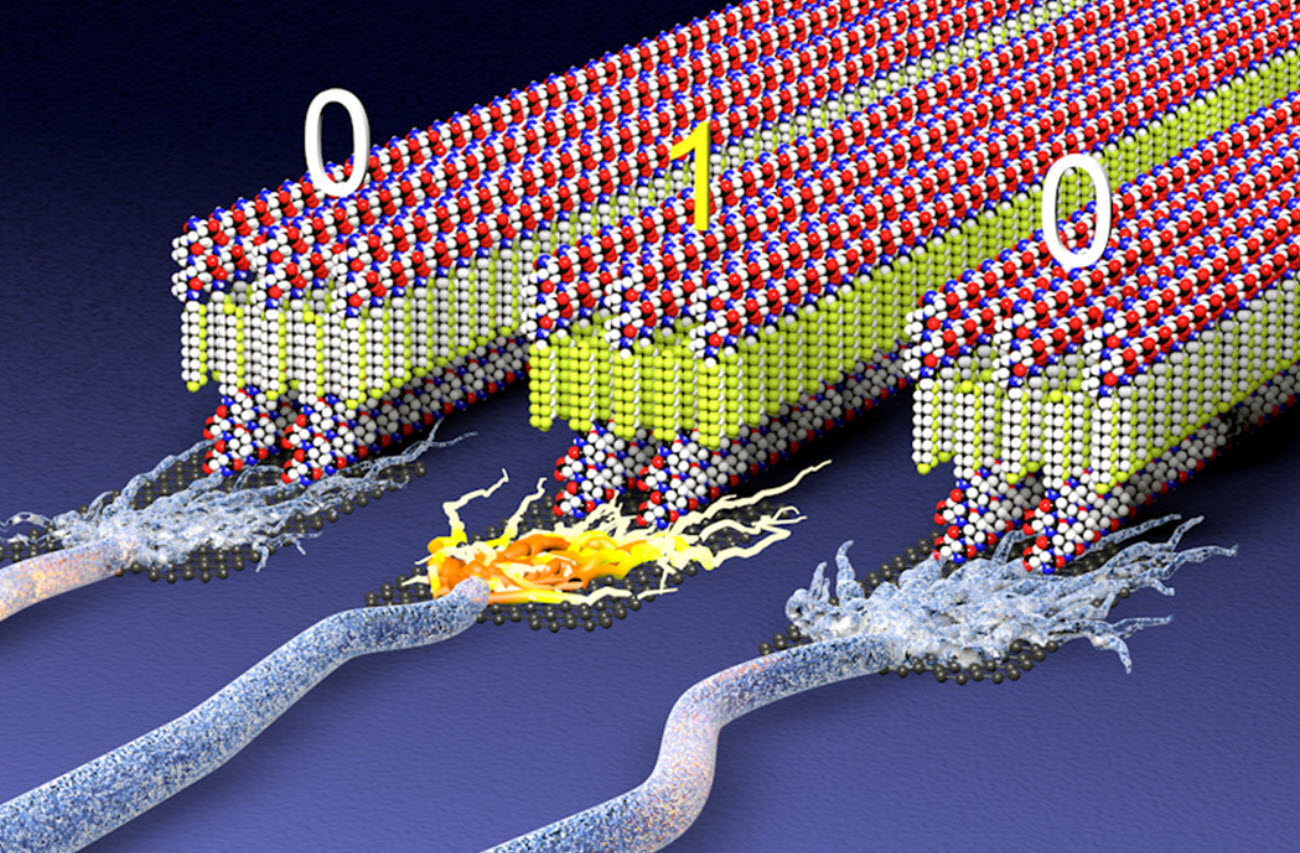

Northwestern University scientists have unveiled a groundbreaking “electric plastic” that could revolutionize medical implants and wearable technology. The research team, led by Samuel Stupp, has developed a remarkable material that combines amino acid chains with polymer plastic. This revolutionary substance requires minimal power to function and can seamlessly interface with human tissue.

The material demonstrates an extraordinary ability to form flexible ribbons when exposed to water. These structures can store energy and record biological signals with unprecedented efficiency. “The self-assembly process happens spontaneously with water,” explains Stupp, highlighting the material’s elegant simplicity.

Technical Advantages

Unlike traditional electronic materials, this new plastic needs 100 times less voltage to operate than existing alternatives. The breakthrough could eliminate the need for bulky pacemakers and transform how we monitor health conditions. The plastic maintains its properties at temperatures up to 110°C, surpassing current technology by 40 degrees.

Potential Applications of electric plastic

Researchers envision a wide range of applications for this revolutionary material. The possibilities stretch from self-powered fitness trackers to clothing with built-in temperature control systems. The material’s unique properties allow it to connect directly with neurons, opening new possibilities for treating neurological conditions.

Scientists could potentially use ultrasound to activate the material wirelessly, offering hope for patients with chronic paralysis. The development team believes their creation could lead to more effective neural interfaces and sophisticated medical monitoring devices.

Environmental Considerations

Despite its promising applications, environmental concerns loom over the electric plastic material’s long-term impact. Experts have raised questions about the fluorinated compounds used in its creation. Some scientists worry about the potential breakdown of these compounds and their persistence in the environment.

European regulators have already proposed restrictions on similar materials due to environmental safety concerns. However, research co-author Yang Yang emphasizes the material’s biocompatibility for medical applications.

Future Prospects

The team now faces the challenge of scaling up production while maintaining the material’s unique properties. Scientists worldwide view this development as a significant step toward integrating technology seamlessly with human biology.

Stupp remains optimistic about finding environmentally friendly alternatives that maintain the material’s revolutionary properties. His team continues to explore new variations of the technology that could address environmental concerns while preserving its breakthrough capabilities.

This development represents a crucial first step toward a future where technology becomes a natural extension of the human body. As research continues, the team hopes to refine their creation into a tool that could transform modern medicine and wearable technology.