A movement is underway in the semiconductor world that could fundamentally change supply balances. The 14A manufacturing process developed by Intel Foundry has caught the attention of industry giants Nvidia and AMD. Capacity bottlenecks and production line congestion at alternative manufacturers like TSMC are pushing major chip designers to seek new solutions.

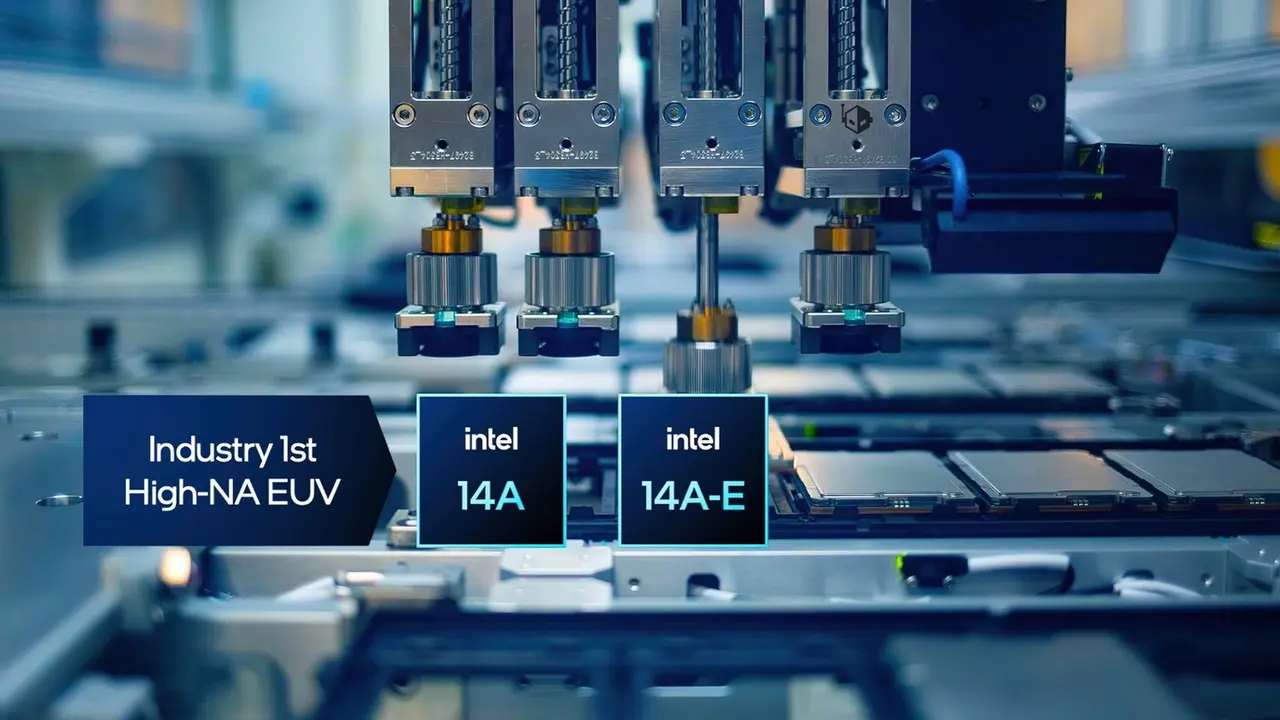

14A Manufacturing Process Sees High Demand

According to data from GF Securities Hong Kong, both Nvidia and AMD have brought Intel’s next-generation manufacturing technologies to the evaluation stage. This interest is not limited to mainstream manufacturing; technology giants like Apple and Broadcom are also seriously considering Intel’s EMIB packaging technology for dedicated server accelerators.

At the heart of this shift in the industry lies the urgent need for advanced packaging solutions. TSMC’s limitations in CoWoS packaging capacity pose a critical obstacle, particularly in the AI and high-performance processor markets.

Intel’s advanced solutions, such as EMIB and Foveros, are becoming attractive again because they provide a performance advantage in complex chip designs. Apple’s process evaluation studies with Intel show that the company has only partially tested Intel’s 18A-P process test kits. Apple is awaiting the release of updated design kits, expected in the first quarter of 2026, for more comprehensive testing.

The project centers around a custom server design codenamed “Baltra,” developed in collaboration with Broadcom. Initially planned for TSMC’s 3-nanometer process, the packaging phase has now shifted to Intel.

As a result of this strategic change, the shipment schedule for these AI server components is projected to be delayed until 2028. However, lower-segment M-series processors manufactured with Intel technology may reach the market as early as 2027.

From Intel’s perspective, this external customer interest is seen as a strategic gain from the billions of dollars the company has invested in manufacturing and advanced packaging. The 14A process promises higher chip density and energy efficiency, increasing competition in the market.