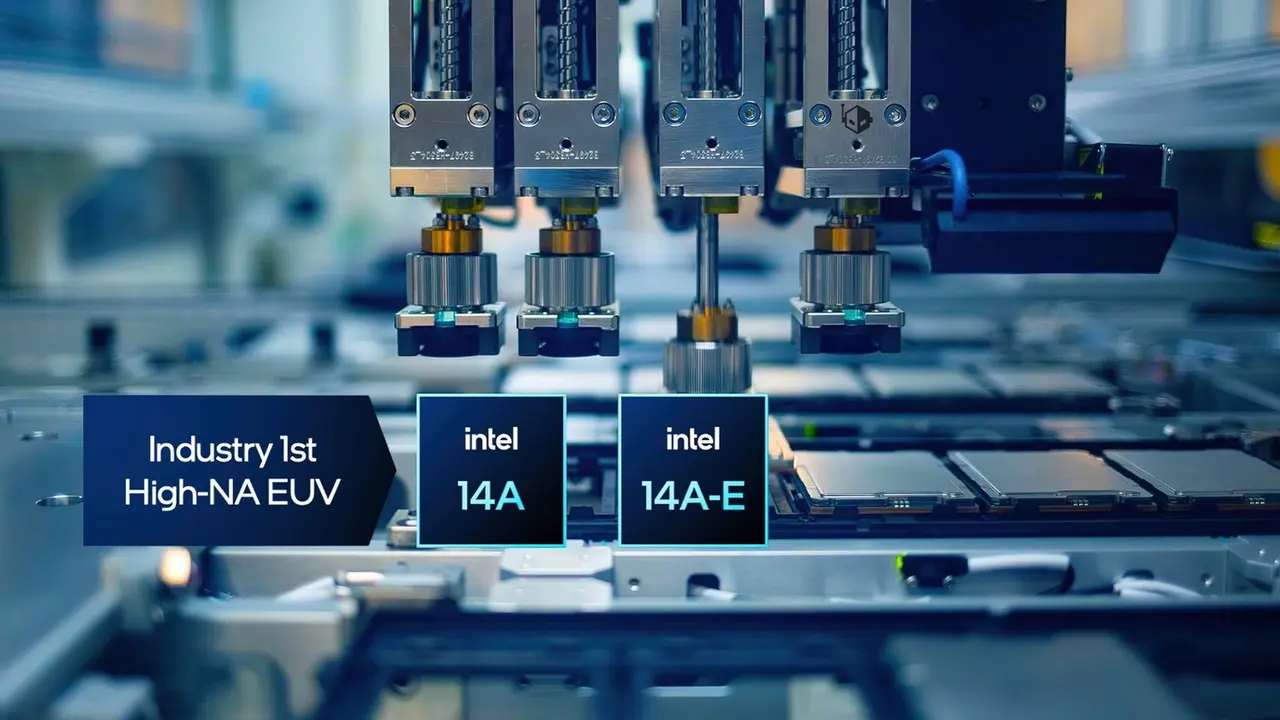

Intel, a leading technology company, has made important announcements about its next-generation 14A manufacturing technology. The company expects this process to deliver a 15% to 20% increase in performance per watt and a 25% to 35% reduction in power consumption. These gains are expected to come from new design approaches like RibbonFET 2 and PowerDirect.

Intel is working on the 14A manufacturing process

Intel’s chief financial officer, David Zinsner, stated that 14A will cost more than 18A. According to Zinsner, this is due to the use of ASML’s High-NA EUV lithography machines, which cost up to $400 million each.

The company plans to share the higher chip costs associated with these machines with external customers. Zinsner also noted that maintaining the 14A process may be difficult without significant external customer support.

Among the key innovations of 14A are special double-layer cells called Turbo Cells. These cells allow CPUs and GPUs to reach higher frequencies without requiring additional space or power consumption.

The 18A process could achieve the target resolution using multiple exposures with existing EUV systems. However, this is insufficient for 14A, which is where ASML’s High-NA EUV machines come in. These high-cost machines, along with billions of dollars in investment in modern chip fabrication and R&D expenses, are driving Intel’s capital expenditures higher.

So, what are your thoughts on this? Share your thoughts with us in the comments section below.