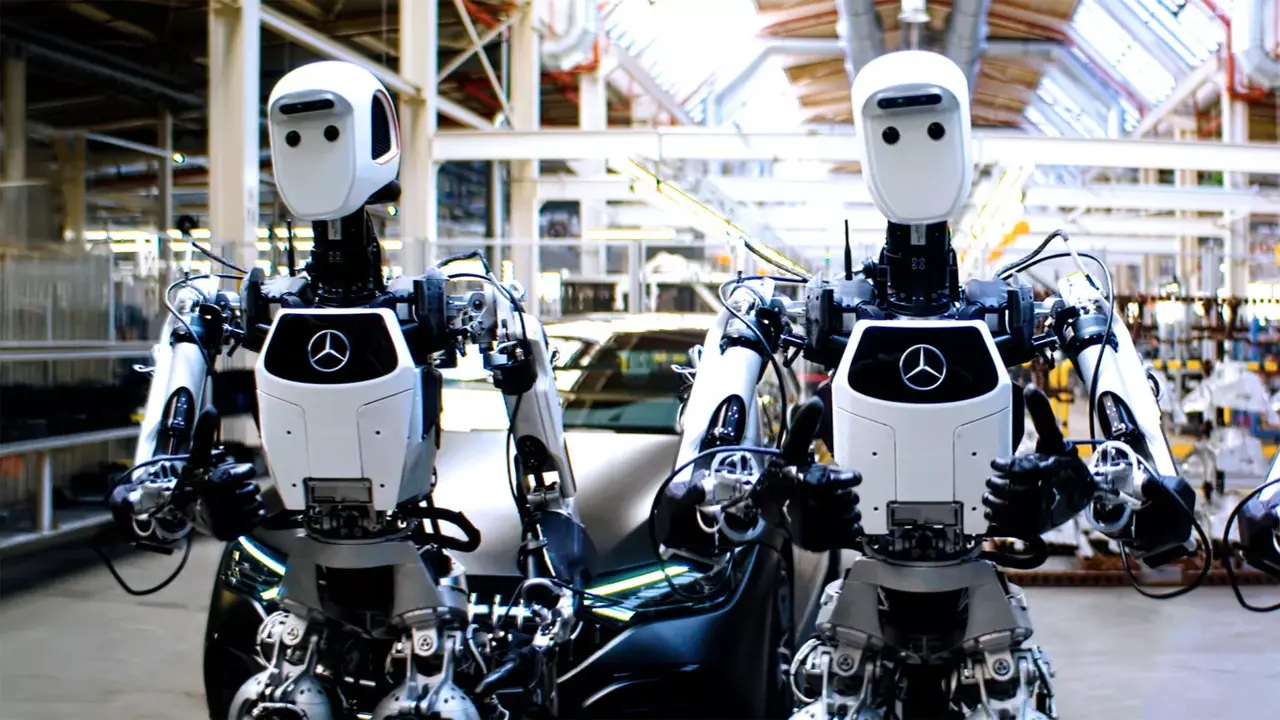

Mercedes has started testing humanoid robots at its factory in Berlin-Marienfelde. The robots, which the company plans to use in production processes, were developed by US-based Apptronik. The company’s Apollo robots, in which Mercedes has also invested, will take part in logistics and quality control processes in the factory.

Mercedes is testing new generation humanoid robots

In the first phase, the robots will be used for component and module handling to assist technicians working on the production line. They are also said to be capable of performing initial quality checks of parts. The robots will be trained through teleoperation and augmented reality. With this method, they will be able to work autonomously over time and their need for human intervention will be reduced.

Among the artificial intelligence-supported capabilities of the robots is the ability to recharge themselves when their batteries are low. In Mercedes’ Digital Factory Campus, the Digital Factory Chatbot is used to access production databases and provide information about machine maintenance.

The use of humanoid robots in the automobile industry will not be limited to Mercedes. Tesla continues to develop its own humanoid robot technology, while BMW commissioned a similar system at its factory in South Carolina last year.

Chinese Dongfeng Motors also started using an artificial intelligence-supported robot in its factory last year. While the integration of humanoid robots into production processes in the automotive industry is gaining momentum, such systems are expected to become more widespread in the coming period. So what do you think about this issue? You can easily share your opinions with us in the comments section below.

Shiftdelete.net

Shiftdelete.net