We know that lithium is a key component of electric vehicle batteries and is of critical importance. Until now, traditional methods of extracting lithium have been associated with environmental risks and low efficiency. But this problem may now be solved. A group of scientists from Rice University in the UK announced a technology that will solve this problem once and for all. Here are the details

UK scientists succeed in extracting 97.5% pure lithium from salt water

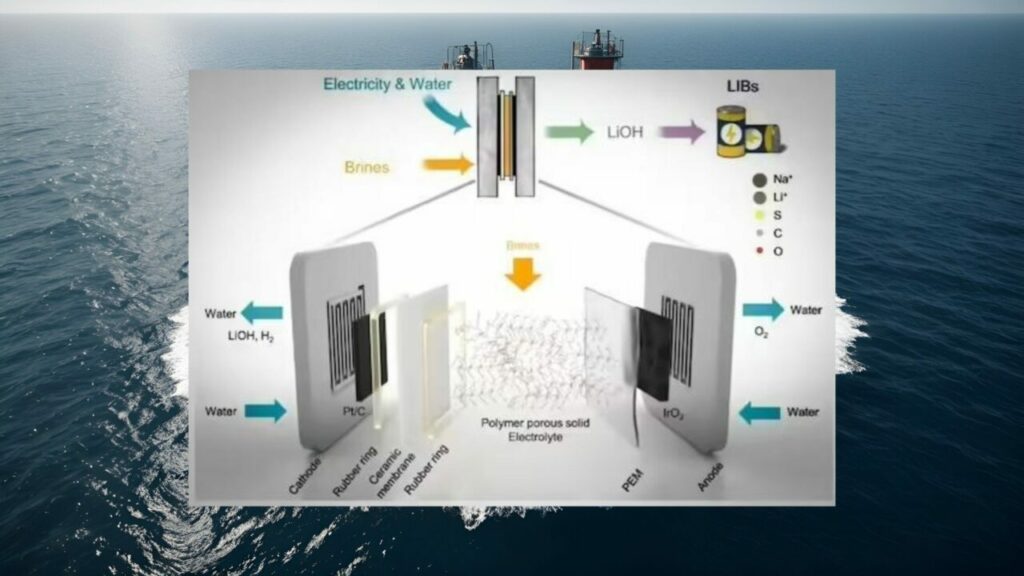

Researchers have designed a new three-compartment electrochemical reactor, in contrast to conventional methods. The newly developed electrochemical reactor is able to extract 97.5% pure lithium from brine sources with minimal environmental impact. But how is this possible?

The porous solid electrolyte material in the central chamber of the reactor selectively separates lithium ions, while leaving out other ions (sodium, potassium, magnesium, calcium). This technology not only achieves high purity lithium, but also prevents the formation of harmful by-products such as chlorine gas.

This method is ideal for the production of high-quality hydroxide lithium used in electric vehicle batteries. The researchers emphasize that the new system is more environmentally friendly compared to conventional methods. Moreover, energy consumption during lithium production is optimized, making the process more efficient.

However, the scientists realized that sodium ions could negatively affect the device’s performance. Strategies are currently being developed to solve this problem, such as adding special coatings to the electrodes and optimizing the electric current. Haotian Wang, a chemical engineering expert from Rice University, said that this technology will soon be further developed by combining basic science and engineering.

What do you think would be the benefits if this method is developed? You can share your opinions with us…