Ceramics are widely used in high-tech fields due to their durability and resistance to high temperatures and corrosion. However, they have a significant drawback: ceramics are brittle and can break easily, limiting their use in some applications. Chinese scientists have made a significant breakthrough by enabling ceramics to exhibit tensile plasticity at room temperature. How did they prevent ceramics from being brittle and make them flexible? Why is this research so important? Here are the details…

World’s First Tensile Plasticity of Ceramics at Room Temperature Achieved

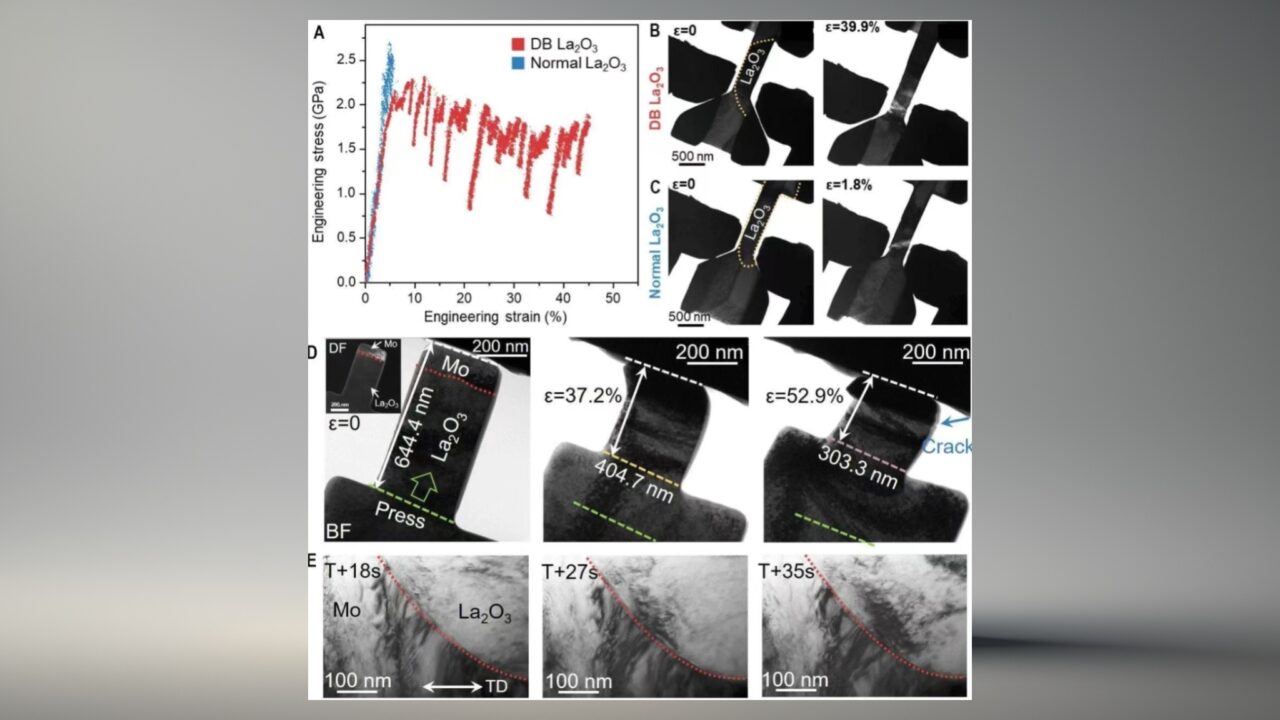

Chinese scientists have succeeded in making these brittle ceramics more flexible. They achieved this by utilizing a mechanism called “dislocation,” similar to that in metals. As a result, ceramics have become resistant to tensile (stretching) forces and can stretch by 39.9%.

This means ceramics will now be more reliable and have a broader range of applications. They will break less and can be used in more places. This development could have a significant impact on the technology and industry sectors, potentially revolutionizing many areas such as more durable electronics, more reliable spacecraft, and stronger structures.

Advances in 3D printing have led to the development of the 4D printing sector. Researchers have successfully produced ceramics using 4D printing.

Advanced ceramic materials are critically important in many high-tech fields due to their superior properties, such as high-temperature resistance, corrosion resistance, high hardness, and low density. However, the brittle nature of ceramics has seriously limited the reliability and application areas of these materials. Therefore, enhancing the durability and plasticity of ceramic materials has been one of the most challenging and important research topics in this field.

Chen Kexin and his team from the University of Science and Technology Beijing previously achieved compressive plasticity in ceramics. Now, in collaboration with Wang Jinshu from Beijing Industrial University and Huang Mingxin from the University of Hong Kong, they have utilized the “borrowed” dislocation mechanism from metals to achieve tensile plasticity in ceramics. With this method, the tensile deformation amount of ceramics reached 39.9%, and their durability reached approximately 2.3 GPa. This discovery completely overturns the general belief that “ceramics cannot have tensile plasticity.”

La2O3 ceramics have successfully demonstrated tensile and bending deformations thanks to the dislocations borrowed from metals. This groundbreaking discovery is expected to expand the application areas of ceramic materials and make a significant impact in the technology world.

You can read all the details of the article published in Science Magazine here. What do you think about this new discovery? Share your thoughts in the comments section below.