A massive education project underway in Qatar is becoming a milestone in construction technologies not only domestically but globally. The project, jointly led by the country’s public works authority, Ashghal, and UCC Holding, aims to build 14 public schools. Two of these schools are being built entirely using 3D printing technology and, by their sheer size, surpass all buildings constructed with this technology to date.

The world’s largest 3D printed structure is set to be unveiled

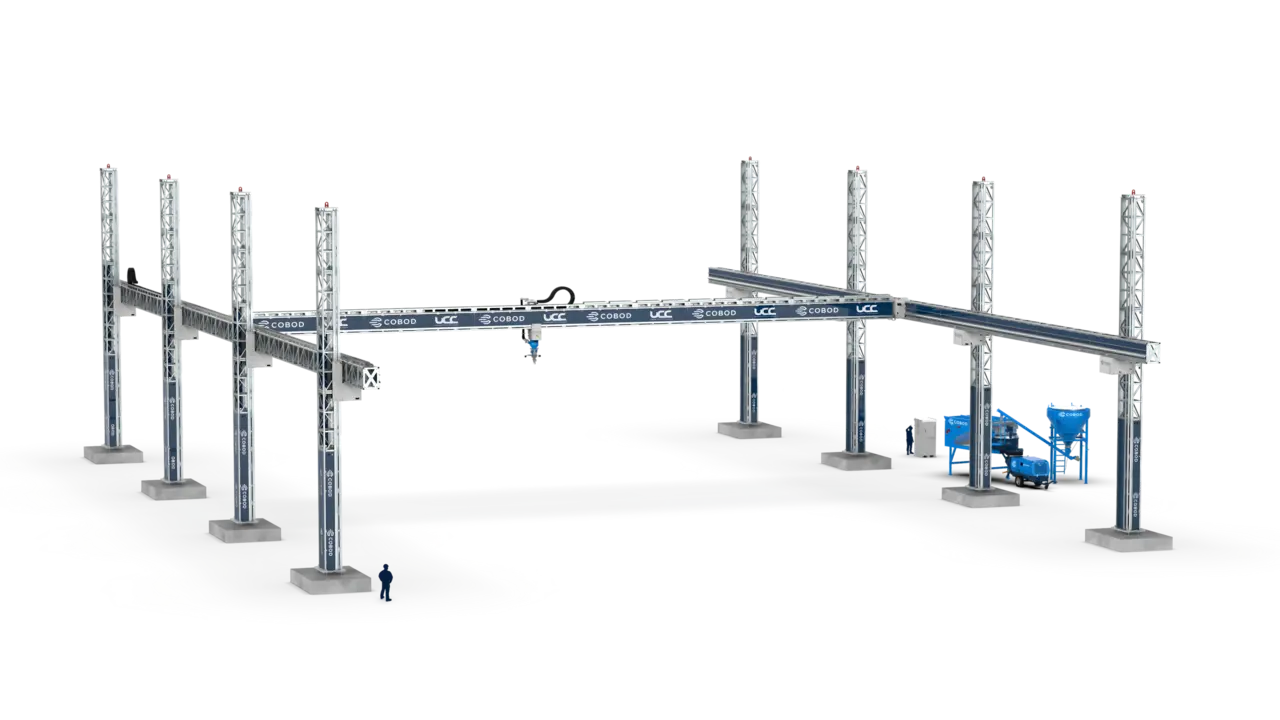

The project utilizes BOD2 XL model 3D printers developed by Denmark-based technology company COBOD. Each printer, measuring 50 meters long, 30 meters wide, and 15 meters high, uses robotic nozzles to deposit a special concrete mixture layer by layer to form the structure’s main frame. Printers will only build the main structure, while complementary elements such as doors, windows, and roofs will be integrated later with human labor.

Each of the two school buildings currently under construction is being designed as two-story buildings with a floor area of 100 square meters. The architectural design is inspired by Qatar’s natural desert topography. Curved and fluid lines, particularly on the walls of the building, will be prominent, reminiscent of desert dunes. No digital images of the structure have been released yet, but it is stated that the forms used will be a far cry from traditional rectangular architecture and will be striking in this regard.

The total construction area covers 40,000 square meters. Each measuring 20,000 square meters, the two 3D-printed schools are approximately 40 times the size of the largest 3D-printed structure ever built worldwide. Considering the materials used and the printer scale, this figure represents both the technological capacity and the new frontier of industrial-scale 3D printing.

The entire school complex is scheduled for completion by the end of 2025. If completed on time, the project could usher in a significant paradigm shift in the role of 3D printing in both the engineering and architecture worlds. These structures, rising from the desert, challenge many assumptions about how reinforced concrete structures will be manufactured in the future.