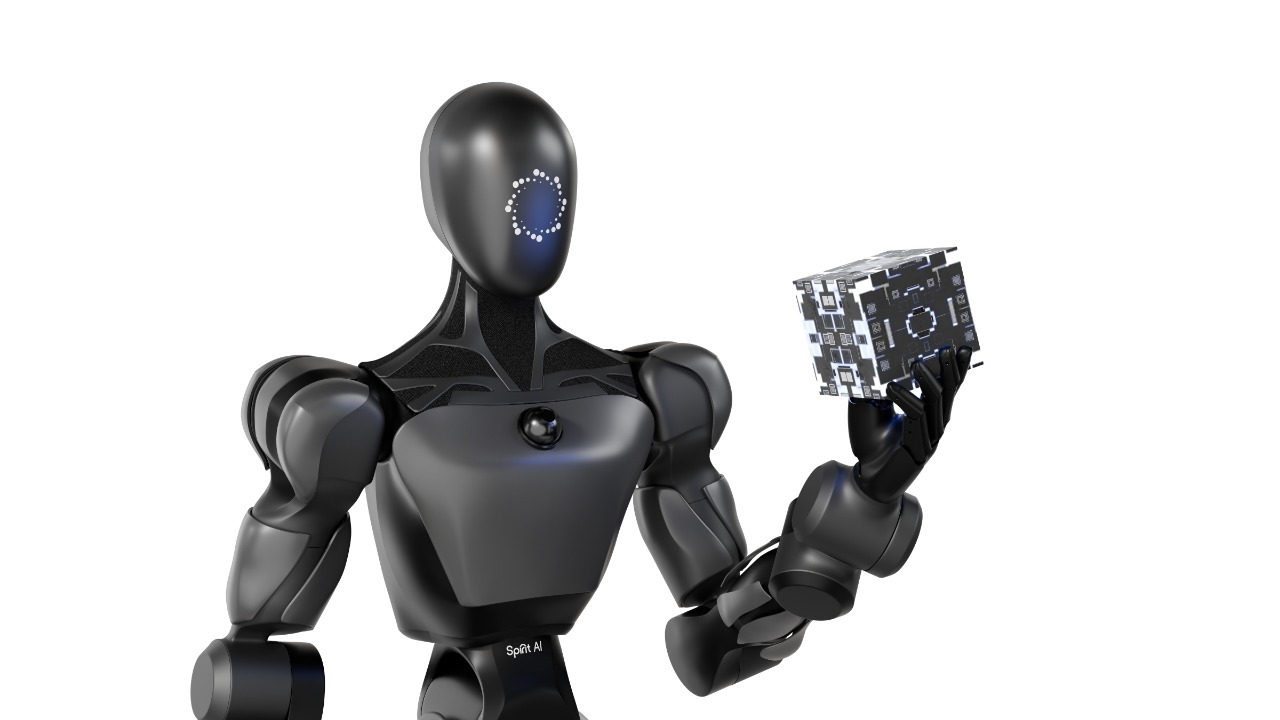

CATL’s Moz robot has quietly leapfrogged Tesla’s Optimus in real-world factory use. While Tesla struggles with performance issues, CATL is already deploying humanoid robots at scale inside one of the most demanding parts of its battery production line.

Moz robot takes lead in factory-floor reality

Tesla’s Optimus may make headlines, but it’s reportedly still dealing with frequent breakdowns and overheating joints. Meanwhile, CATL has moved faster. Its Spirit AI division created the Moz robot and placed it directly into high-precision EV battery assembly.

According to CATL, Moz now operates inside the “world’s first power battery pack production line” with full-scale humanoid robot integration. Unlike simple crate-stacking tasks, Moz works at critical quality control points handling battery connectors and wiring with care and speed that CATL claims match experienced human technicians.

Moz robot reaches 99% precision in complex tasks

The company says Moz is delivering a 99% insertion success rate. That’s thanks to an advanced vision model that adjusts in real time. The robot can respond to material misalignment and varying connector positions, modifying its posture and force with human-like finesse.

Moz also knows how much pressure to apply when securing fragile battery harnesses, avoiding wire damage while maintaining speed. CATL says its robot demonstrates strong spatial awareness and the ability to adapt quickly to new conditions without retraining.

Here’s what sets the Moz robot apart:

- 99% accuracy in connector insertion

- Real-time adaptation to position changes

- Controlled force application for fragile components

- Vision-guided motion and posture correction

- Deployment at quality assurance checkpoints

Moz robot highlights China’s rapid AI robotics push

The achievement isn’t happening in a vacuum. China’s humanoid robotics sector has exploded, with dozens of AI firms chasing large-scale automation. Some analysts believe it’s already on track to overproduce humanoid robots much like the country’s EV and battery markets.

Still, CATL’s ability to put a robot like Moz into mass production ahead of Tesla sends a clear message: it’s not just about flashy prototypes, it’s about who gets machines on the factory floor first.

A quiet but major milestone

The Moz robot may not have danced onstage like Optimus, but it just matched skilled human labor in one of the most demanding manufacturing roles around. That’s more than a flex, it’s a shift in how battery giants are thinking about their future workforce.

The humanoid race just got real and CATL may have pulled ahead without anyone noticing.