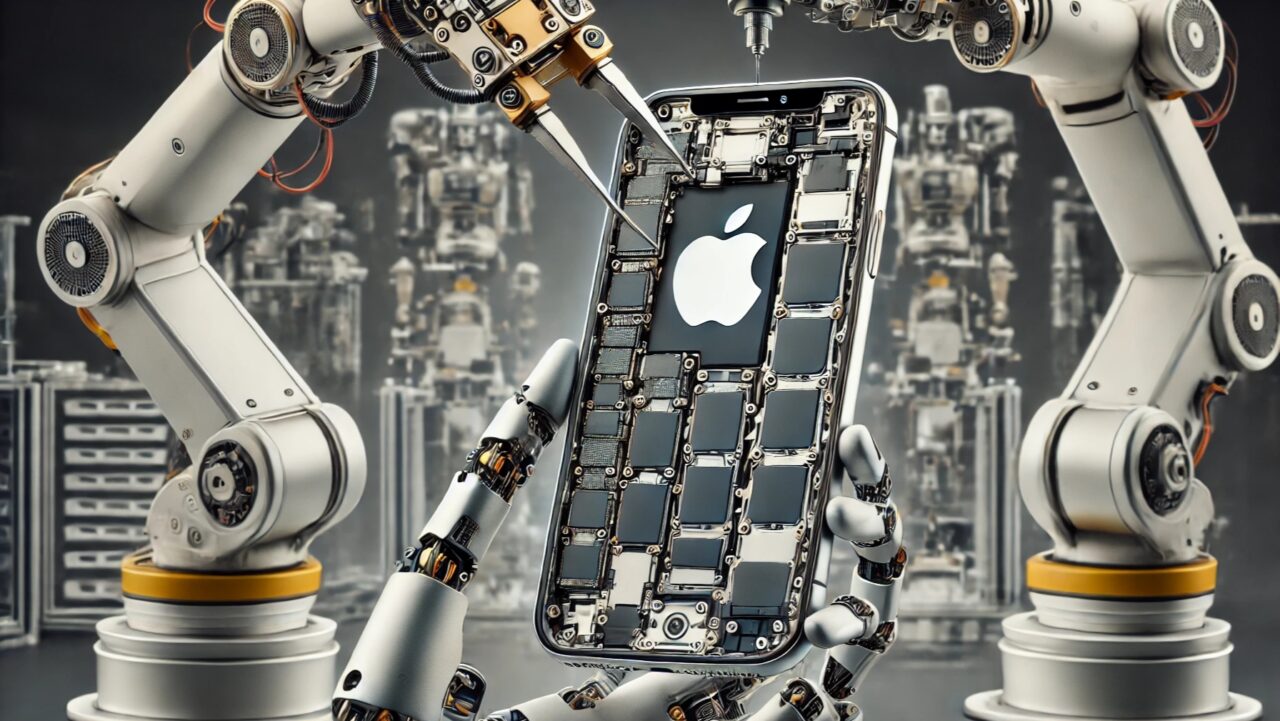

Apple has made a significant decision to automate the iPhone assembly process. From now on, your iPhone devices and many other Apple products will be assembled by robots and AI-powered automation systems. Why did Apple make this decision? Here are the details…

Apple is moving to automation in iPhone assembly: The number of workers will be reduced by 50%

It all started with COVID-19-related lockdowns and protests in China affecting major suppliers like Foxconn. These events caused disruptions in production processes, leading Apple to seek alternative solutions to produce iPhones and other products smoothly. This is where the idea of robots and automation systems came into play.

Apple plans to make a major transformation by using robotic technologies and AI-powered automation systems on the production line. A significant portion of iPhone parts will be precisely assembled by state-of-the-art robots. This will not only reduce production costs but also increase product consistency.

This automation decision will be applied not only in iPhone production but also in the assembly of other Apple products. The integration of robots and AI systems will accelerate production processes, minimizing potential disruptions in the supply chain. Additionally, this technology enables a more sustainable and environmentally friendly production process.

Of course, such a large-scale automation change also brings some concerns. The reduced need for human labor in all Apple products, including iPhones, may cause some fluctuations in the labor market. However, it will also create new job opportunities. New expertise areas will emerge for the maintenance, programming, and management of robots and AI systems.

What do you think about this? How do you think this automation move will affect the industry? Don’t forget to share your thoughts with us in the comments below!