To overcome the production efficiency challenges it has experienced in recent years, Samsung has focused on the 2-nanometer (nm) manufacturing process. The low yield rates the company has encountered, particularly in the 3nm GAA process, have led to the suspension of orders from key customers, particularly Qualcomm. To reverse this trend, Samsung plans to increase efficiency in 2nm production to 70% by the end of the year.

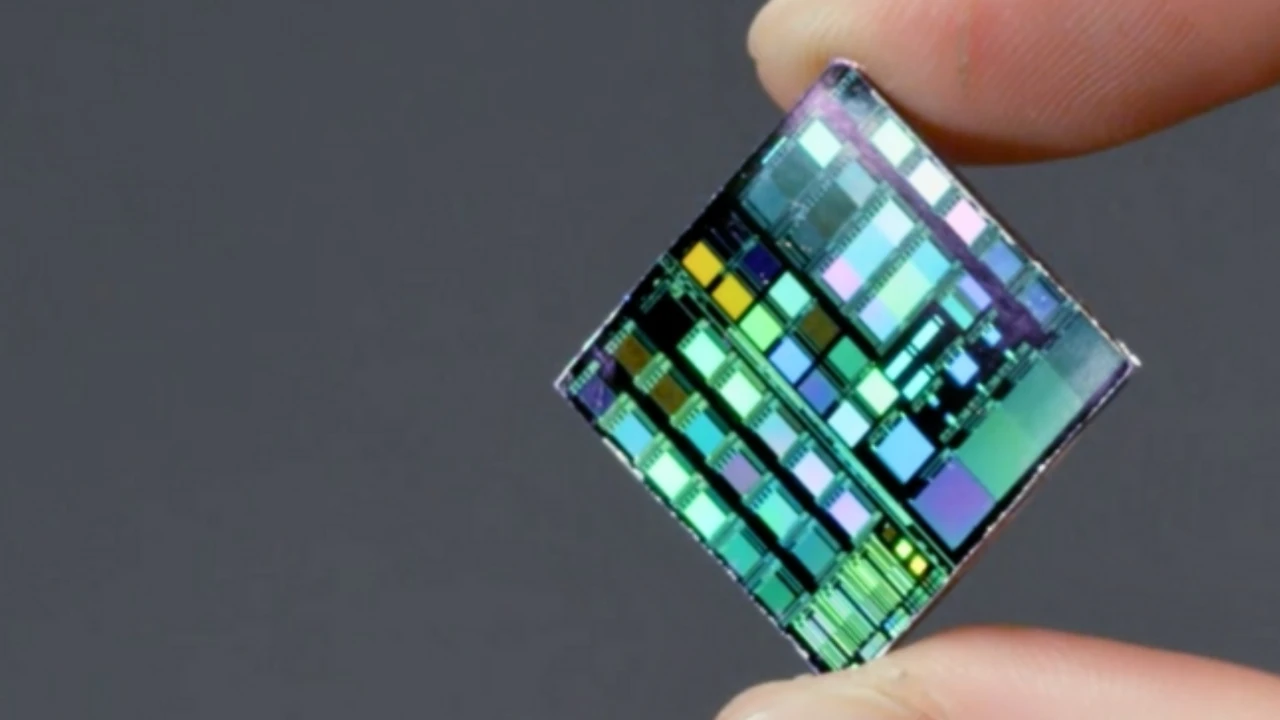

Samsung Re-emerges with 2nm Production

The efficiency rate, currently around 30%, is targeted to reach 60 to 70% by the end of 2025. This improvement is said to be critical to regaining major customers like Qualcomm.

Rumors previously surfaced that Samsung had received orders for the Snapdragon 8 Elite Gen 2 using its 2nm production process. While this information has not been officially confirmed, it indicates that Qualcomm continues its manufacturing relationship with Samsung.

Samsung is not only increasing efficiency; it is also improving its technological infrastructure. Having completed the fundamental design of its second-generation 2nm GAA process, the company plans to deploy its third-generation 2nm manufacturing technology, known as SF2P+, within two years. These developments form the technical foundation of Samsung’s efforts to regain its strength against its rival, TSMC.

The company’s target for mass production of 2nm production remains the beginning of 2026. However, recent updates indicate that production capacity will be increased before this date, starting in the second half of the year.

Samsung’s success in this process depends on securing repeat orders from major customers and fulfilling these orders on time. Increased productivity, in particular, is considered the most critical factor in paving the way for commercial success.